| The Hot Liquid Tank is made of a cut out keg. It has 45' of 1/2" I.D. soft copper tubing inside to form the heat transfer with full stainless steel bypass ball valves outside and a water drain. The boil water may also be pumped out of the HLT and directed back into the mash tun through the sparging H-manifold for sparging or cleaning.

|

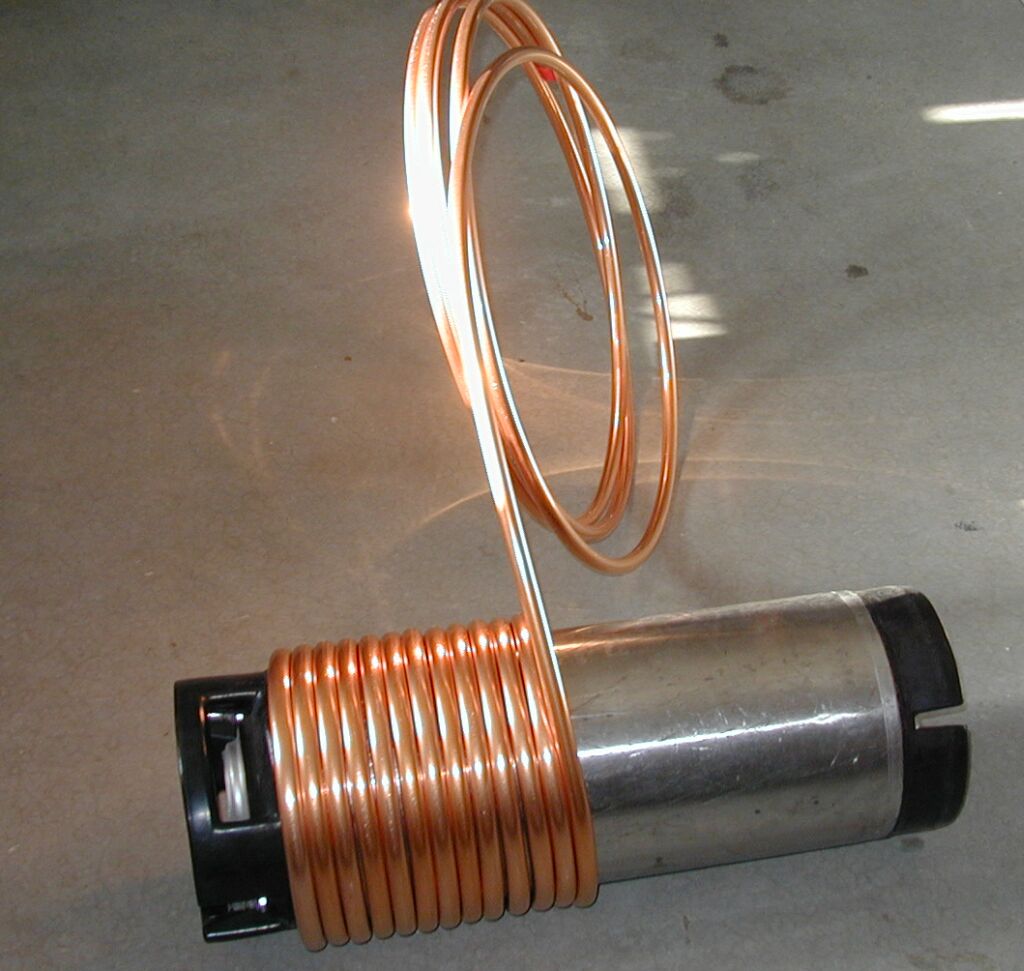

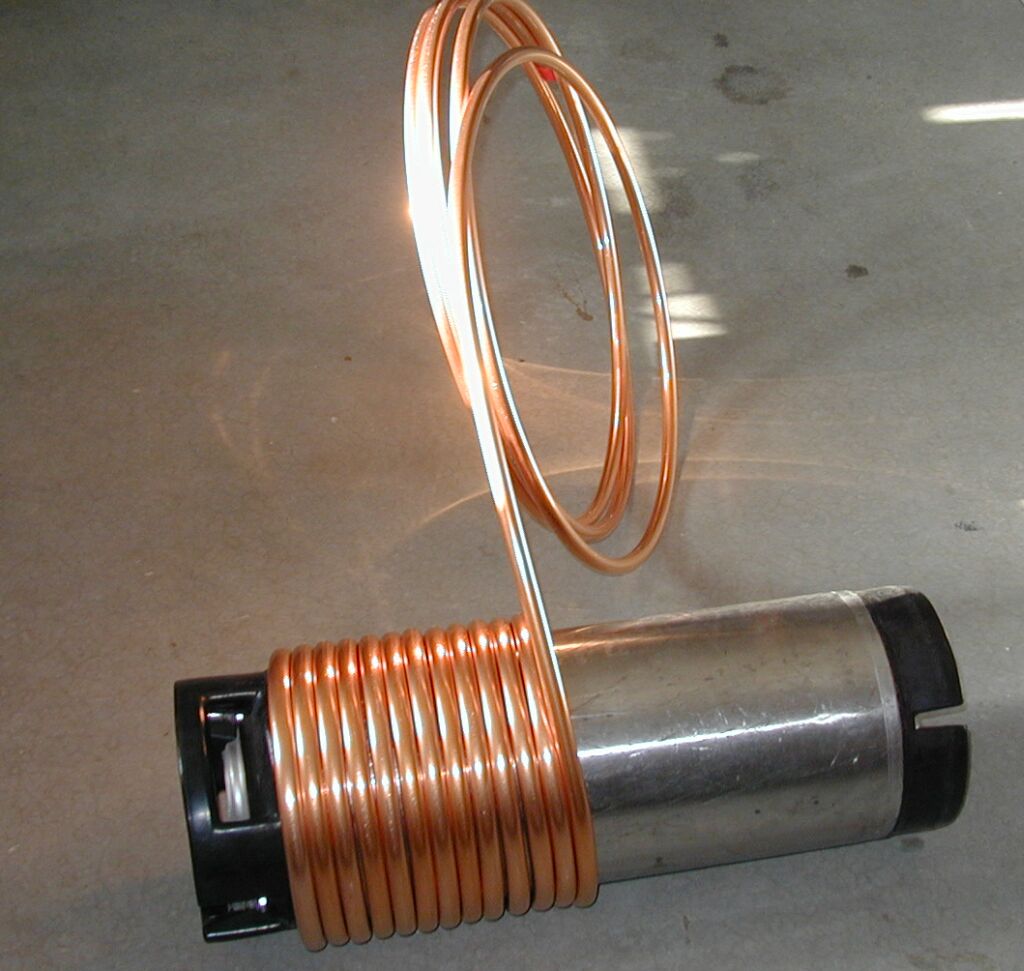

| Wrapping the heat transfer coil around an 8" Corny keg works quite well.

|

| Care should be taken to not wrap it too tight and to keep the coils wrapping close to each other. Slightly wrapping on top of the last coil helps keep them very close.

|

| Be careful not to push down too hard on the keg while rolling it, or the soft tubing will mash down flat (it will naturally do this a little as you bend it to the tighter diameter). The final height of the tubing is about 17" and gave me about 20 coils in 47' (once the ends were cut back).

|

| Here is the final product with the ends cut back with exactly 20 coils. I've put 90' fittings on the ends to begin getting the 1/2" I.D. rigid pipe that will eventually go into the compression fittings on the inside to allow me to remove the coil if need be.

|

| This is a shot of the coil sitting inside the HLT kettle.

|

| And another, once mounted up to the welded SS 1/2" couplers and then the 1/2" MPT to 5/8" compression fittings.

|

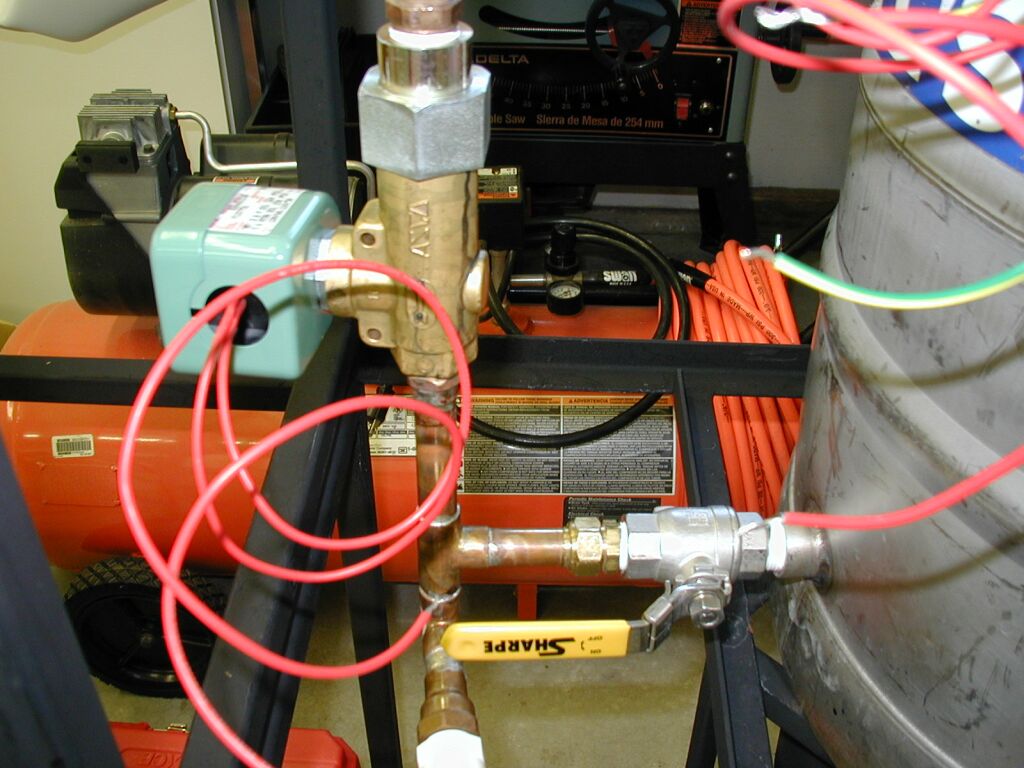

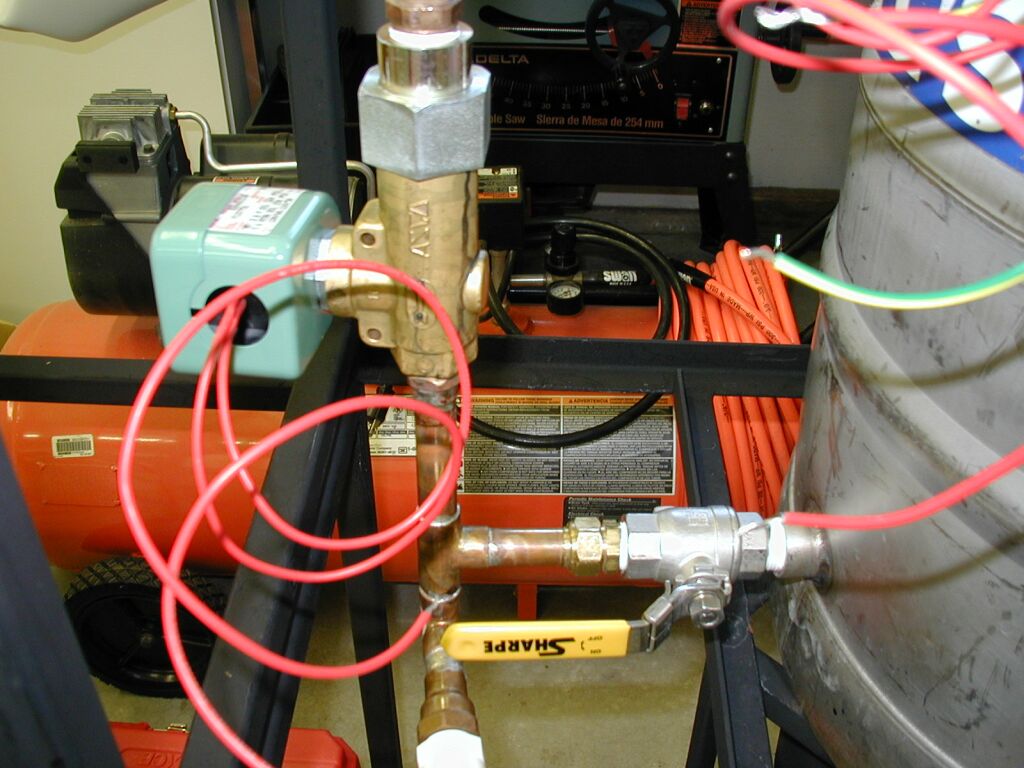

| I just upgraded the HLT to have an electronic temperature controlled (ETC) solenoid valve for the heat/bypass. The ETC is a Ranco digital control, and the temperature pick up goes in the mashtun and controls the bypass valves in the HLT.

|

| This is the normally open solenoid valve in the heat transfer coil leg and is open when the ETC shows the temperature is too cool.

|

| This is the normally open solenoid valve in the bypass leg and is open when the ETC shows the temperature is hot enough.

|

| Here is another picture of the latest changes to the bypass. I removed the old mis-matched ASCO valve in the bypass vertical line and put a new matched on in that has better flow rate (the old one was only 3/16").

|